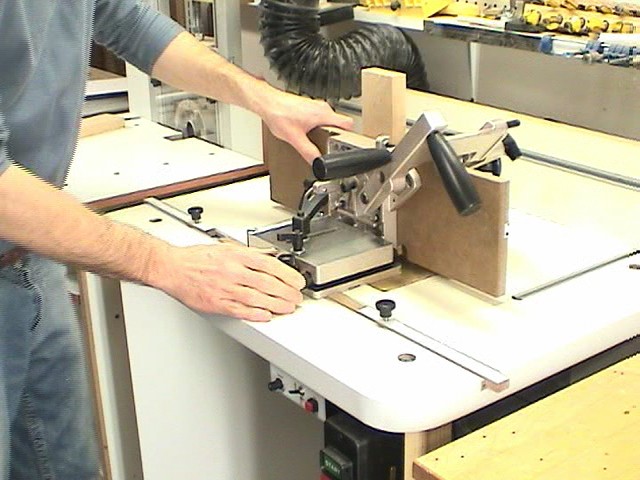

The tenon jig I use on the Router Table for mortising is from Rockler:

http://www.rockler.com/product.cfm?page=10185&filter=tenon%20jig

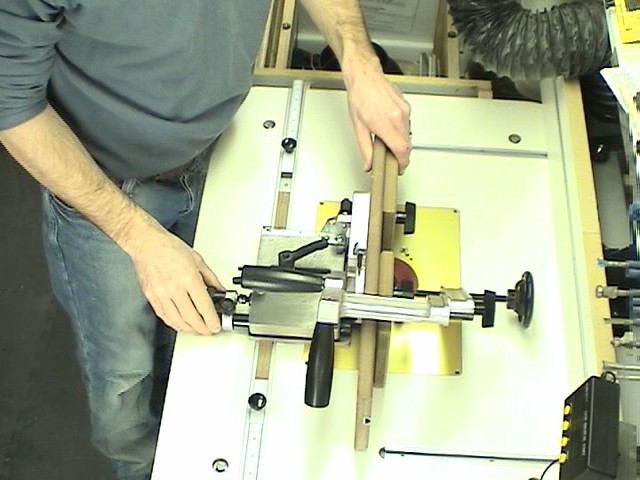

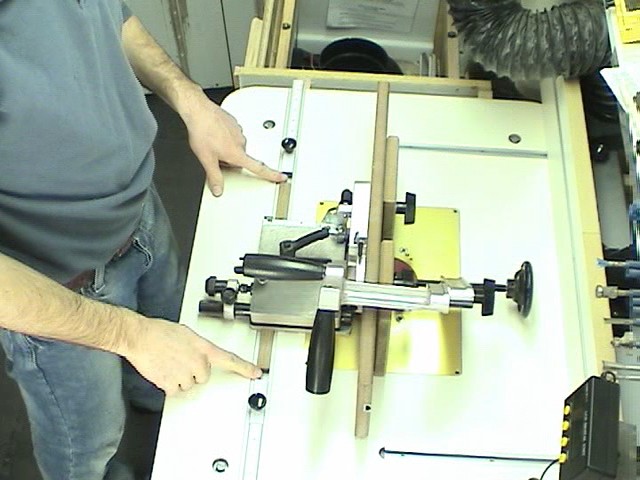

Using a tenon jig to control the lateral movement of the workpiece works out really well for mortising, sliding dovetails, and tenons. Routing operations where you need to control the movement of the workpiece may benefit from the use of a tenon jig. If your router table is equipped with a Motorized Router Lift, you can turn your router table into an efficient and effective mortising machine.

I've looked at 3 or 4 other heavy duty tenon jigs, and they seem basically the same. The one thing I will say for the Rockler one, that I'm not sure is on the other jigs, is two sets of holes in the bottom for mounting the miter slide in two different positions. This will in effect get you closer or farther from the bit. It can be handy when mortising larger stock. The other models may have this, I just don't know for sure.

I added the wide face with the t-track to the tenon jig. The broad face is really just a coated piece of MDF with a shallow t-track running horizontally across it. This addition allowed for the use of stop blocks for reproducible cuts and provides added clamping pressure and stability to the workpiece. There's a vertical support piece on the original face that I removed. I also relocated the arm that has the screw clamp. I just used another set of holes that was already on the jig.

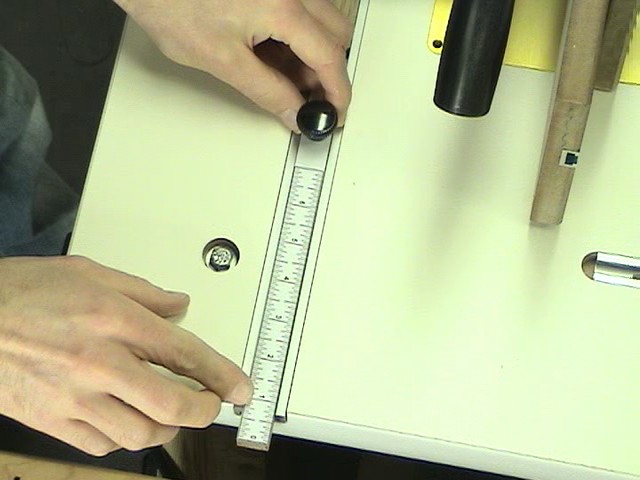

If you are interested in finding out how to make the rulered stops that go in the miter track to control the travel of the tenon jig, click here.

Here's some pictures of the tenon jig (note: I painted it, but it's still the Rockler jig)