The Super Sled combines two of my best shop jigs!

I love my original crosscut sled, so when you (the viewers) asked me to make a video about how to make that sled, I started to think of ways to improve upon the existing design.

I regularly use two different sleds in my shop:

1. My crosscut sled which I use mainly for crosscutting, and cutting shoulder cuts on tenons.

2. Wood Magazines Universal Tablesaw Jig which I use exclusively for mitering.

While contemplating ways to improve on the design of my crosscut sled, I started to focus on the concept of combining the two sleds. I spent a lot of time modeling the new Super Sled in Google Sketchup and I feel I have come up with one of the most versatile crosscut / mitering sleds around. When you see the video for the construction of the sled, I think you'll be surprised at how easy it is to build for yourself!

The video for how to build the SuperSled will be filmed later this month (Feb 2009)

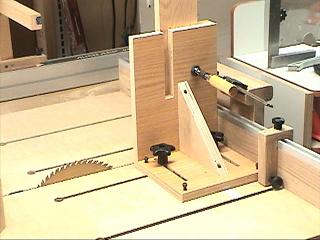

Crosscutting

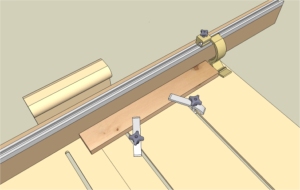

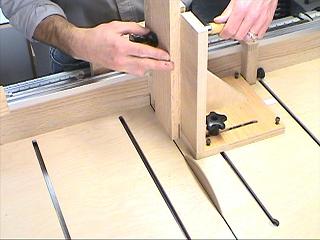

The Super Sled has all the benefits of my original crosscut sled, including a t-track for adjustable stop blocks. The new sled uses a flip stop, so you can keep the stop in the same place, but flip it up out of the way to make other cuts in between.

With generous capacity to the left and right of the saw blade, the Super Sled can handle just about any crosscut. The main fence is extended out farther on the left side of the blade allowing you to use the flip stop for long cuts. |

|

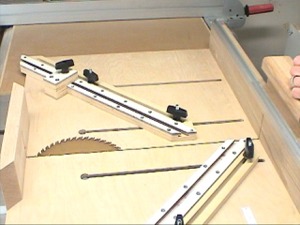

Mitering

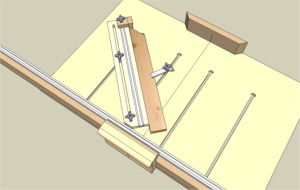

I really love mitering with Wood Magazines Universal Tablesaw jig which is why I wanted to incorporate all the features of this jig into the Super Sled. The Universal Tablesaw jig needs to be switched from one side of the blade to the other when doing complementary miters. With an identical setup on both sides of the blade, you can easily miter on either side of the blade.

The fence used for mitering has a t-track for mounting a stop block or hold downs and can be positioned any where from 0 to about 70 degrees. |

|

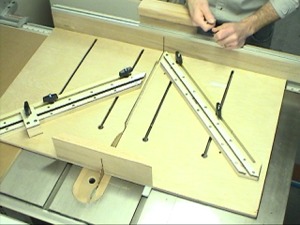

Versatility

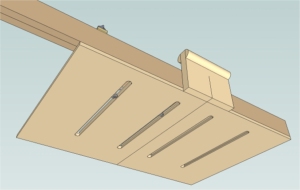

I designed the Super Sled with versatility in mind. The four slots in the main board of the fence function the same as t-tracks, and allow for the inclusion of stop blocks, the miter fence, and other add-on jigs like a tenon or box joint jig.

The main board for the super sled is 1/2 inch plywood. I went with 1/2 inch plywood so I wouldn't loose very much blade height capacity. The four slots in the main board are 3/8 inch wide from the top, and have a 3/4 inch wide shallow recess in the bottom and will accomodate a standard 5/16 inch t-bolt. |

|

Update - 3/22/2009: There are now two Accessory videos available. The Stop Block and the Tenon Jig have been added to the video collection.

Update - 4/05/2009: Mitering Fence Video Released - The latest video in the Super Sled series shows the construction of the fence and two different kind of stop blocks. The setup process for mitering with the fence is also shown.

A friend of Eagle Lake writes an informative Instructables article describing the steps to make his souped up version of the Super Sled - Joe Laviolette made some really cool additions to the Super Sled design - one notable improvement is the concept of a removable zero clearance insert. Read all about Joe's sled and how to make it in this well documented pictorial tutorial:

http://www.instructables.com/id/How-to-make-a-better-cross-cut-sled/

A friend of Eagle Lake offers some Super Sled improvements: Bob McCormick came up with two great suggestions for improving the usability of the Super Sled. The first suggestion was a great find - a right angled t-track that has a t-track on the top and a second t-track at a right angle to the first. Bob mounted this t-track to the main rear fence after cutting a rabbit. Having a a t-track on the top and face of the fence opens up some nice possibilities for mounting accessories.

The second improvement Bob came up with is great - he designed a simple solution to stow the miter fences on the back of the main fence. He installed some threaded inserts into the back of the main fence where he can mounted the miter fences by using a thumbscrew to hold it in place.